Products Center

Contact Us

Tel / WeChat / Telegram:

WhtasApp:

E-mail:

hebeiyidi2019@gmail.com

670248293@qq.com

Office:

Weissi East Road, Xindian New District, Hui Autonomous County, Mengcun, Cangzhou City, Hebei Province, China

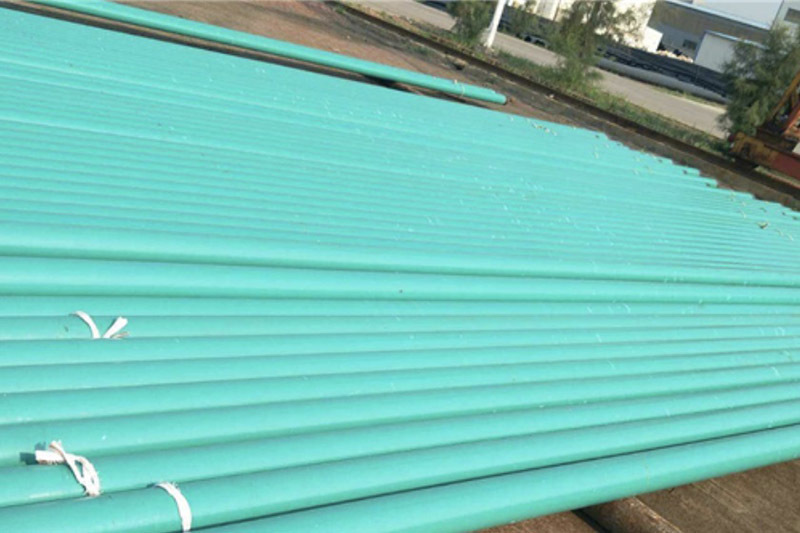

UV resistant gas special coated steel pipe

- Commodity name: UV resistant gas special coated steel pipe

- Product Description

-

UV resistant gas specific coated steel pipe is a type of steel pipe that is coated with a plastic coating with UV resistance on its surface. It is mainly used for gas transportation and has excellent UV resistance and anti-corrosion properties.

Product features

● Anti UV: Anti UV additives such as carbon black and titanium dioxide are added to the coating, which can effectively absorb or reflect UV rays, preventing the steel pipe from aging, fading, or becoming brittle due to prolonged exposure to sunlight.

● Anti corrosion performance: The inner layer is usually made of plastic materials with excellent corrosion resistance, such as polyethylene (PE) or epoxy resin (EP), which can block the chemical substances and moisture that may exist inside the pipeline, ensuring that the gas will not undergo harmful chemical reactions with the pipe wall during transportation.

● Three layer structure: Gas specific UV resistant coated anti-corrosion steel pipes have a three-layer structure, including an inner layer of corrosion-resistant plastic, a middle layer of adhesive, and an outer layer of UV resistant plastic. This structure ensures the sealing and stability of the pipeline, preventing gas leakage.

Application area

UV resistant gas coated steel pipes are widely used in the field of gas transportation, especially in outdoor environments where they perform well. They are suitable for the gas pipeline network and household gas pipeline in residential areas, ensuring the safety and stability of gas transmission.

Production process

● Surface pretreatment: Oil and rust removal treatment is usually carried out on steel pipes, using chemical cleaning or mechanical polishing methods to ensure that the surface of the steel pipe is clean and smooth, which is conducive to the adhesion of plastic coatings.

● Coating process: including immersion coating method and spray coating method. The immersion coating method is easy to operate and can ensure the uniformity of the coating; The spraying method is suitable for steel pipes with complex shapes, and can accurately control the thickness and position of the coating.

● Curing treatment: After coating, the coating needs to be cured to dry and harden the coating, forming a stable coating. The curing method varies depending on the type of coating, for example, thermoplastic coatings can be cured by heating, melting, and cooling, while thermosetting coatings can be cured by cross-linking through chemical reactions.

Key words:

Get A Quote

NOTE: Please leave your email, our professional person will contact you asap!

Tel / WhatsApp:

E-mail: