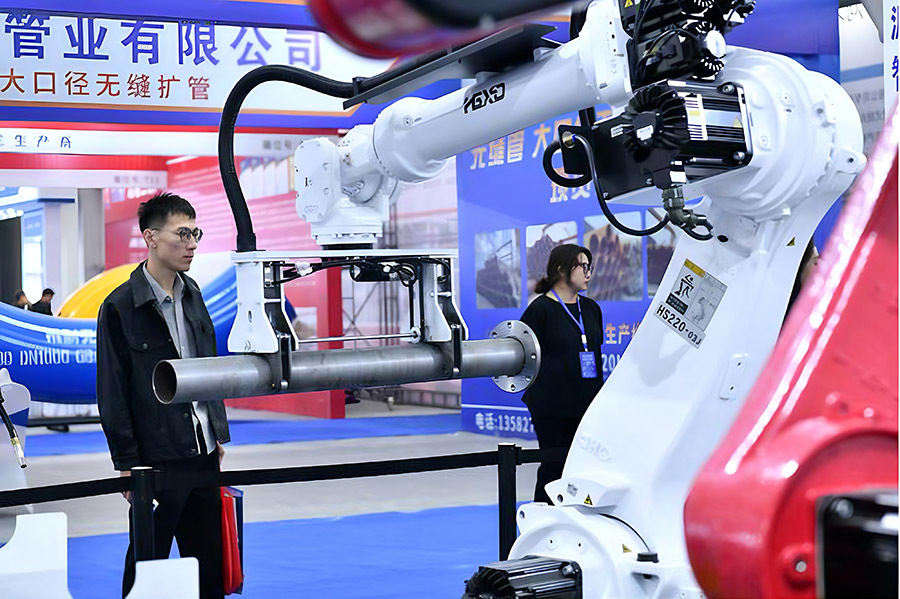

Production Strength

| Production line | Start-up time | Technical certification | Core application case |

| Thermal insulation pipe production workshop | Put into operation in September 2019 | EN 13941 (District heating) | Russian Siberian Extreme Cold Heating Project (-45℃) |

| 3PE and epoxy powder coating line | Operation from March 2020 | API 5L/ISO 3183 | Kazakhstan Crude Oil Pipeline (300 km supply) |

| Gas pipeline Coating plastic production line | It is planned to be put into operation in 2021 | ISO 21809-2:2020 | Ho Chi Minh City Gas Pipeline Network Renovation Project |

Cooperation Value

Technical Depth × Scenario Experience

- Overcome extreme working conditions such as -50℃ gas transmission in the Arctic Circle and 70℃ high temperature oil transmission in the Middle East

- Obtained 12 anti-corrosion and insulation technology patents, and R&D investment increased by 25% annually

Zero Defect Quality Commitment

- Raw material traceability system (support SGS batch inspection report)

- 100% helium leak detection + third-party DNV GL certification

Global Service Network

- Quick response: MIN order size 100 meters, 15 days delivery of standard orders

- Localization support: Technical Service Center in Germany/Middle East/Southeast Asia

- Multilingual collaboration: English, Russian, Spanish, Arabic project docking team

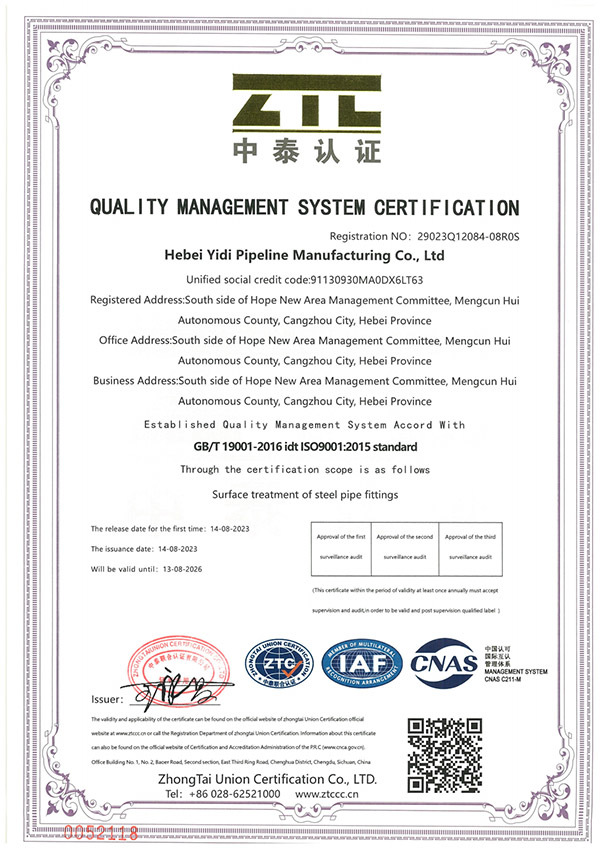

Qualification

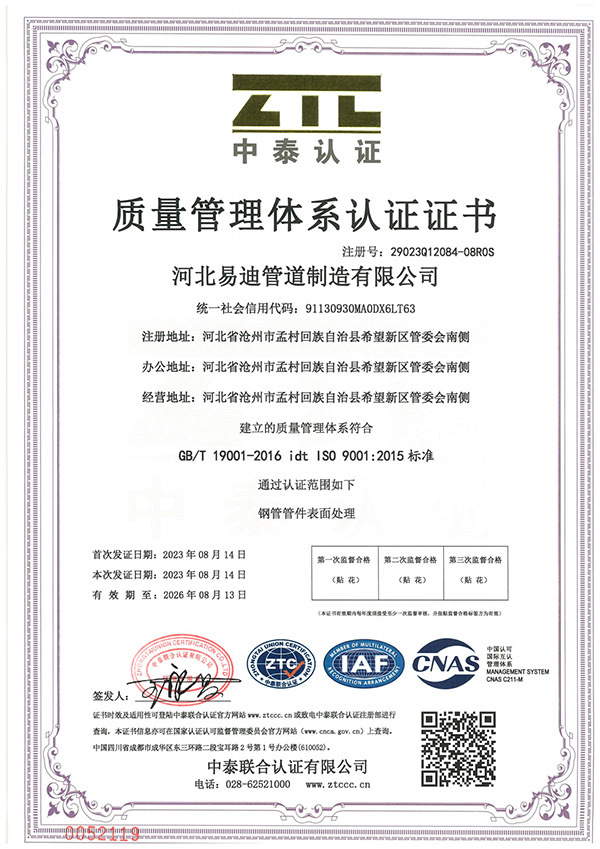

Quality Management System Certification

Quality Management System Certification

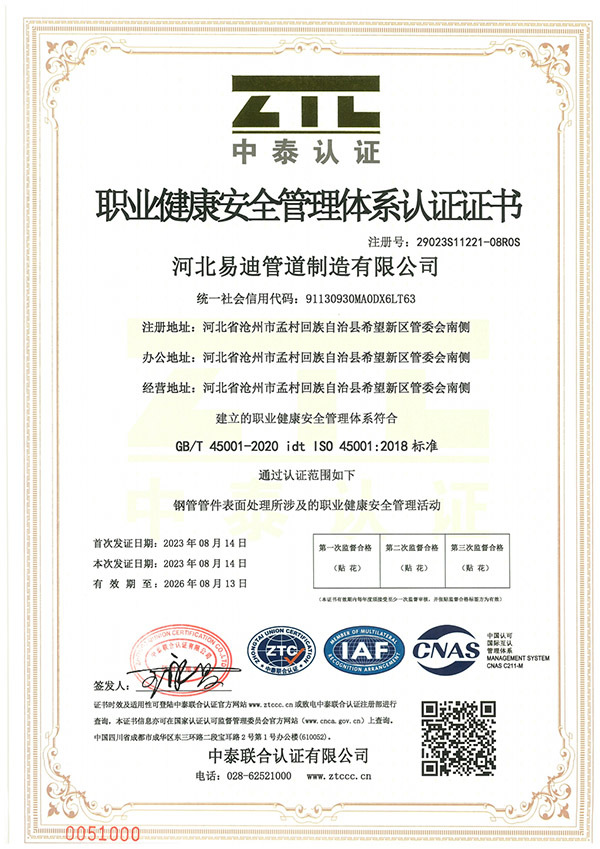

Occupational Health And Safety Management System Certification

Occupational Health And Safety Management System Certification

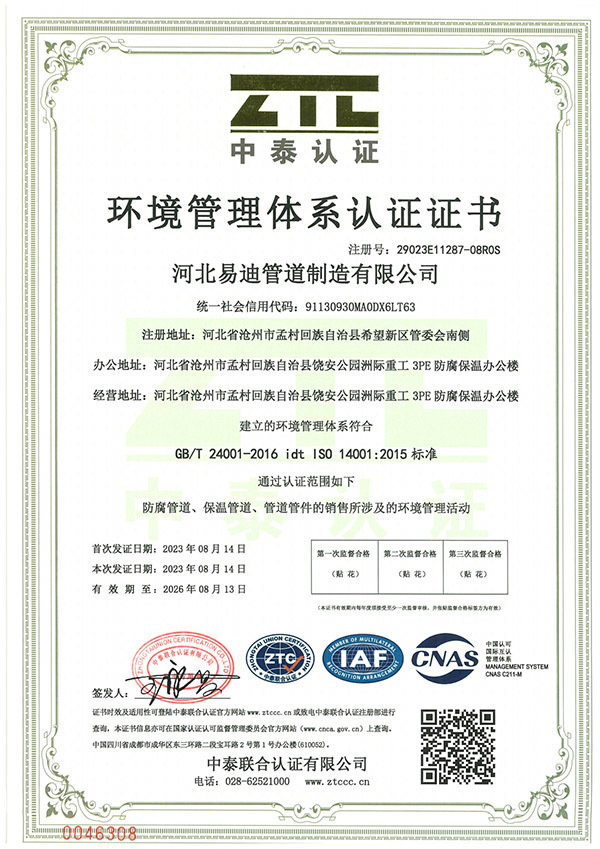

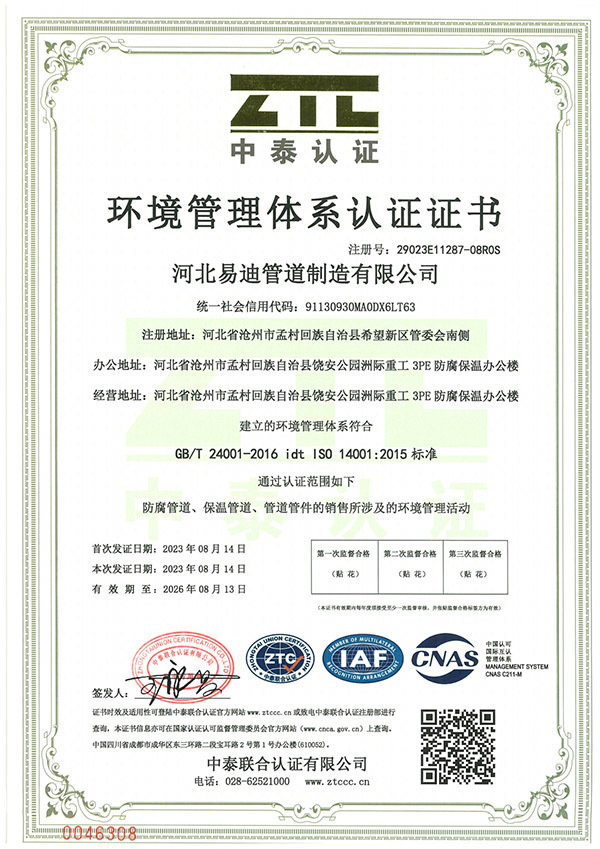

Environment Management System Certification

Environment Management System Certification

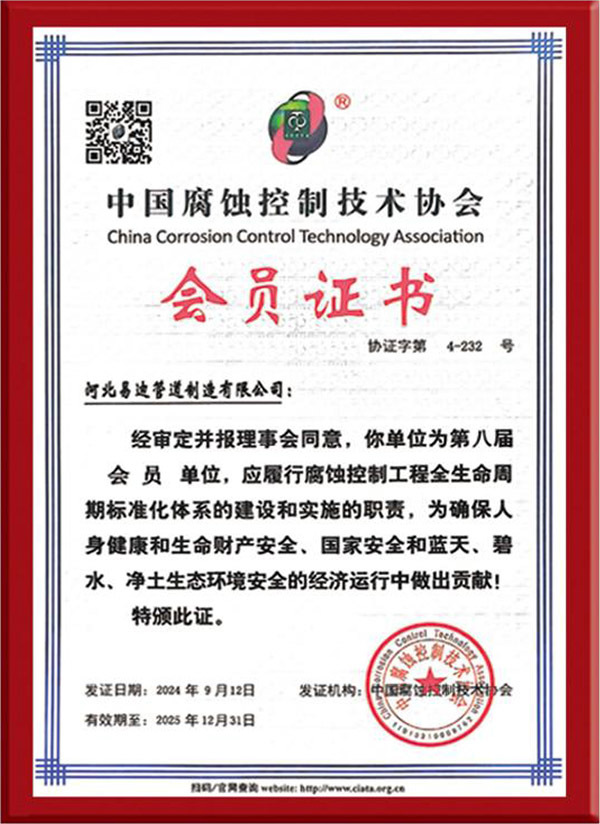

Membership certificate

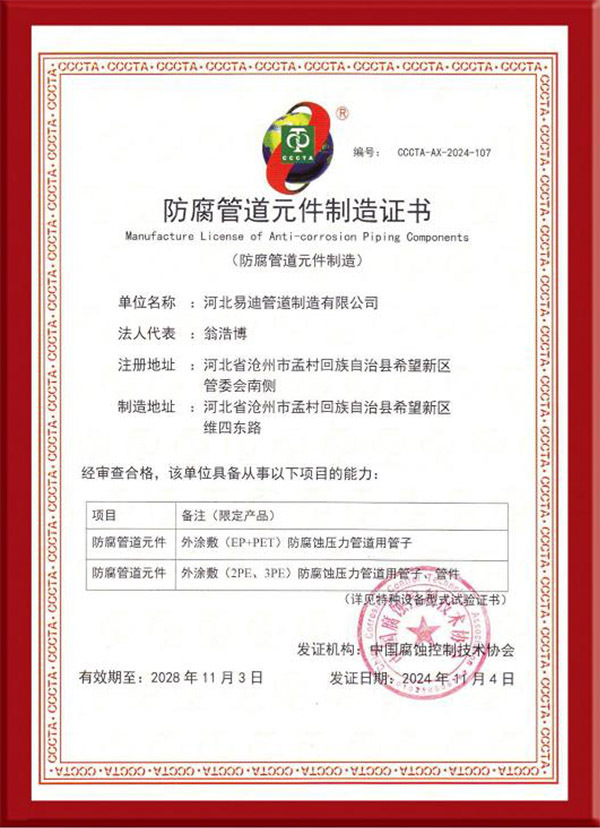

Anticorrosive pipe original manufacturing certificate

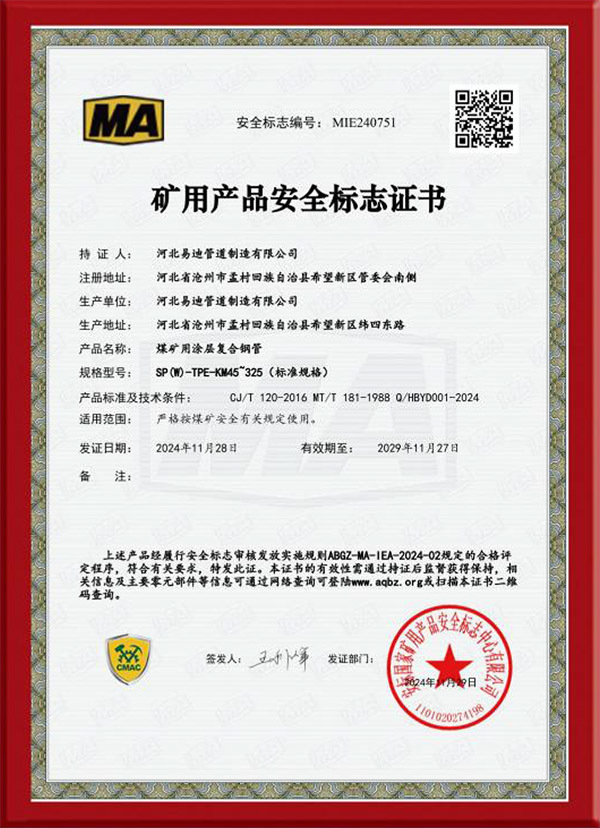

Safety mark certificate for mining products

Safety mark certificate for mining products

Factory Tour

Tel / WhatsApp:

E-mail: