Products Center

Contact Us

Tel / WeChat / Telegram:

WhtasApp:

E-mail:

hebeiyidi2019@gmail.com

670248293@qq.com

Office:

Weissi East Road, Xindian New District, Hui Autonomous County, Mengcun, Cangzhou City, Hebei Province, China

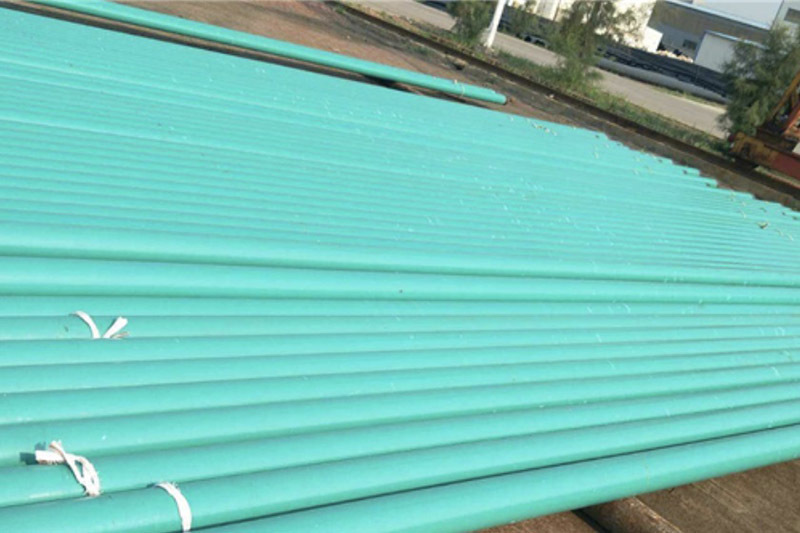

Internally and externally coated anti-corrosion steel pipes

- Commodity name: Internally and externally coated anti-corrosion steel pipes

- Product Description

-

Internally and externally coated anti-corrosion steel pipe is a composite pipe material coated with plastic material on the inner and outer surfaces of the steel pipe, usually using organic compounds such as polyethylene (PE), ethylene acrylic acid copolymer (EAA), epoxy resin (EP), non-toxic polypropylene (PP) or non-toxic polyvinyl chloride (PVC). This design not only retains the advantages of high strength and easy connection of steel pipes, but also overcomes the disadvantages of water corrosion and low strength of plastic pipes. The design life can reach 50 years.

Structural characteristics and application fields

The structure of inner and outer plastic coated anti-corrosion steel pipes includes a steel pipe substrate and a plastic coating layer. The steel pipe matrix can be carbon steel or low-alloy steel, such as Q235B, Q345B, etc., providing good strength and toughness. The thickness of the coating layer is usually 0.5-1.0mm. The inner coating is mainly used to prevent medium corrosion, while the outer coating is used to resist external environmental corrosion.

This type of steel pipe is widely used in the following fields

● Water supply and drainage system: used for tap water and sewage treatment to prevent water pollution.

● Oil and gas industry: used for transporting crude oil and natural gas to prevent pipeline corrosion.

● Chemical industry: Transport various chemical media to resist chemical corrosion.

● Heating system: used in centralized heating pipelines to improve system safety and economy.

Manufacturing process and maintenance methods

The manufacturing process of internally and externally coated anti-corrosion steel pipes includes the following steps:

● Surface treatment: Remove rust, oil stains, and oxide scales from the surface of steel pipes, usually using chemical pickling or mechanical polishing methods.

● Coating spraying: The treated steel pipe is sprayed with plastic coating material to form a uniform coating, which can be achieved by electrostatic spraying or thermal spraying.

● Baking and curing: After the coating is sprayed, it needs to be baked and cured to ensure the wear resistance and anti-corrosion performance of the coating.

When installing and maintaining, the following points should be noted:

Choose the appropriate coating material based on the usage environment and medium. During installation, bending, hot working, and welding cutting operations are not allowed. The cutting surface needs to be repaired with non-toxic room temperature curing adhesive.

Key words:

Get A Quote

NOTE: Please leave your email, our professional person will contact you asap!

Tel / WhatsApp:

E-mail: