Products Center

Contact Us

Tel / WeChat / Telegram:

WhtasApp:

E-mail:

hebeiyidi2019@gmail.com

670248293@qq.com

Office:

Weissi East Road, Xindian New District, Hui Autonomous County, Mengcun, Cangzhou City, Hebei Province, China

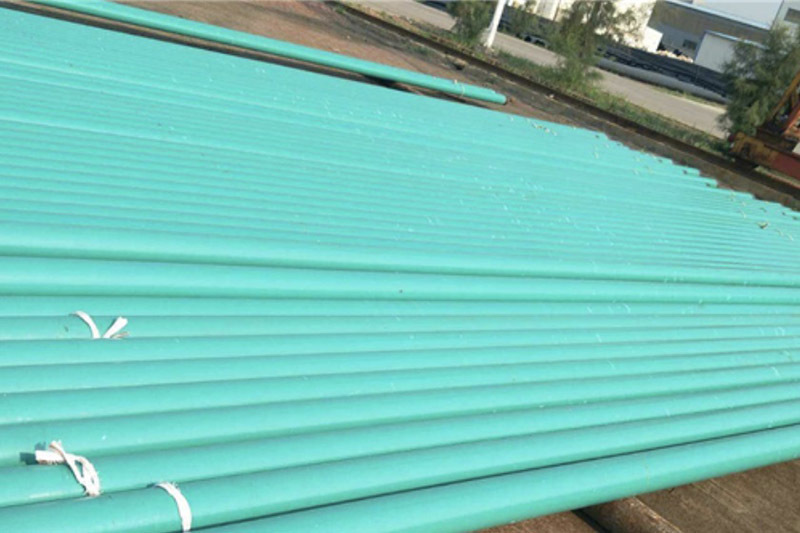

Epoxy coal tar anti-corrosion steel pipe

- Commodity name: Epoxy coal tar anti-corrosion steel pipe

- Product Description

-

Epoxy coal tar asphalt anti-corrosion steel pipe is a high-performance anti-corrosion material, mainly composed of epoxy resin, coal tar asphalt, anti rust pigments, and additives. It has the characteristics of rapid drying, strong adhesion, good flexibility, acid resistance, alkali resistance, salt resistance, water resistance, oil resistance, etc. The core anti-corrosion strength of epoxy coal tar anti-corrosion steel pipes comes from the exquisite fusion of epoxy resin and coal tar. Epoxy resin provides a stable skeleton and excellent chemical resistance, while coal tar, with its hydrophobicity and antimicrobial properties, jointly provides strong protection for steel pipes.

Performance characteristics

● Chemical resistance: Epoxy coal tar anti-corrosion steel pipes can effectively block the penetration of corrosive media such as acids, alkalis, and salts.

● High mechanical strength: Its tensile strength can reach over 200MPa, with excellent tensile and bending properties.

● Strong adhesion: The coating is tightly connected to the steel pipe substrate and will not peel off even under complex external forces.

● Strong adaptability: able to maintain stability in environments ranging from -30 ℃ to 100 ℃, ensuring that the coating does not crack or peel off.Application scenarios

Epoxy coal tar anti-corrosion steel pipes are widely used for anti-corrosion of equipment and pipelines in oil pipelines, gas pipelines, water pipelines, water pipelines, gas pipelines, refineries, chemical plants, and sewage treatment plants. They are also suitable for anti-corrosion of underwater parts of offshore oil drilling platforms and ships. In addition, it is also used for anti-corrosion of mining and underground equipment.

Key words:

Get A Quote

NOTE: Please leave your email, our professional person will contact you asap!

Tel / WhatsApp:

E-mail: