Products Center

Contact Us

Tel / WeChat / Telegram:

WhtasApp:

E-mail:

hebeiyidi2019@gmail.com

670248293@qq.com

Office:

Weissi East Road, Xindian New District, Hui Autonomous County, Mengcun, Cangzhou City, Hebei Province, China

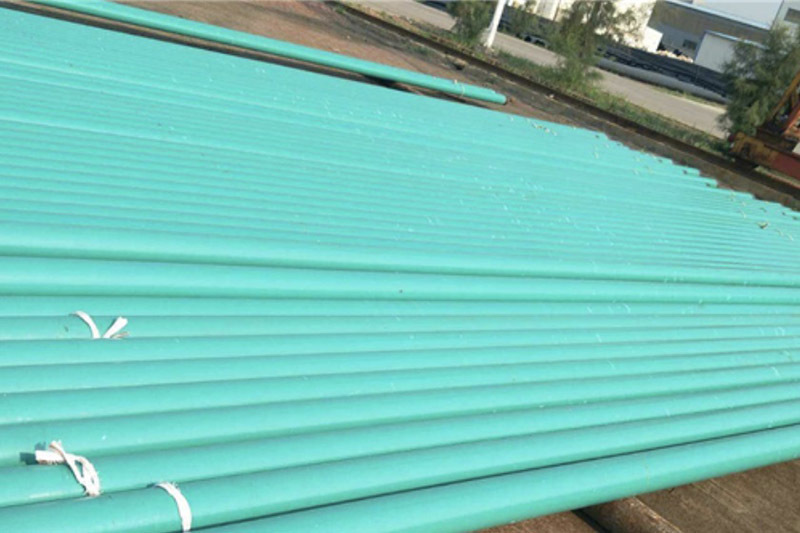

3PE anti-corrosion steel pipe

- Commodity name: 3PE anti-corrosion steel pipe

- Product Description

-

3PE anti-corrosion steel pipe is a type of steel pipe that uses a three-layer polyethylene (3PE) anti-corrosion structure and is widely used in industries such as water, gas, and petroleum. Its structure consists of epoxy powder coating, adhesive layer, and polyethylene outer layer from inside to outside, which makes the 3PE anti-corrosion steel pipe have excellent anti-corrosion performance and good mechanical strength.

Structural characteristics

● Epoxy powder coating: As the bottom layer in direct contact with steel pipes, epoxy powder coating has excellent adhesion and anti-corrosion properties, which can tightly adhere to the surface of steel pipes and effectively prevent them from coming into contact with corrosive media from the outside. Its thickness is generally between 120-200 μ m, with a stable chemical structure that can resist the erosion of various chemical substances.

● Adhesive layer: located between the epoxy powder coating and the polyethylene outer layer, its main function is to firmly bond the two together. The thickness of the adhesive layer is usually between 170-250 μ m, which has good bonding performance and ensures that the three-layer structure will not delaminate under various environmental conditions. Its composition has been specially designed to adapt to different temperature and humidity changes, ensuring the integrity of the entire anti-corrosion system.

● Polyethylene outer layer: As the outermost protective structure, the polyethylene outer layer has good weather resistance, corrosion resistance, and mechanical damage resistance. Its thickness is generally between 2.2-3.7mm, which can effectively resist ultraviolet radiation, chemical substances in the atmosphere, and physical wear.

Application area

3PE anti-corrosion steel pipes are widely used in pipeline engineering fields such as petroleum, chemical, natural gas, thermal, sewage treatment, water sources, bridges, steel structures, and marine water transmission pile driving. Its excellent anti-corrosion performance enables it to maintain long-term stable operation even in harsh environments, especially in acidic soil, alkaline soil, saline soil areas, and marine environments where it performs excellently.

Production process

The production process of 3PE anti-corrosion steel pipes includes the steps of shot blasting, rust removal inspection, heating, powder coating, adhesive coating, and polyethylene coating after the bare pipe is heated at medium frequency. Strict spraying and leak detection ensure the integrity and quality of the anti-corrosion layer.

Key words:

Get A Quote

NOTE: Please leave your email, our professional person will contact you asap!

Tel / WhatsApp:

E-mail: